FOOD SAFETY

Creation Gardens, Inc. DBA What Chefs Want, operates a state of the art food processing and distribution establishment. In 2015 Creation Gardens updated and remodeled the 90,000 square foot distribution and production facility to include improvements to production lines, material handling processes, and sanitation equipment. 2016 Creation Gardens, Inc. expanded the Louisville facility by addition of a second floor and installation of voice directed order retrieval and powered conveyor systems throughout the distribution areas of the warehouse. 2018 Creation Gardens commissioned the newly constructed Prep Kitchen™ fresh cut fruits and vegetable processing facility in Cincinnati, Ohio, and Spring of 2019, Creation Gardens welcomes Bluefin Seafoods™ into a new Louisville seafood processing facility. Creation Gardens, Inc. food manufacturing and processing facilities meet the regulatory criteria of USDA and FDA for processing facilities and are designed dedicated to producing the safest and most wholesome food products available.

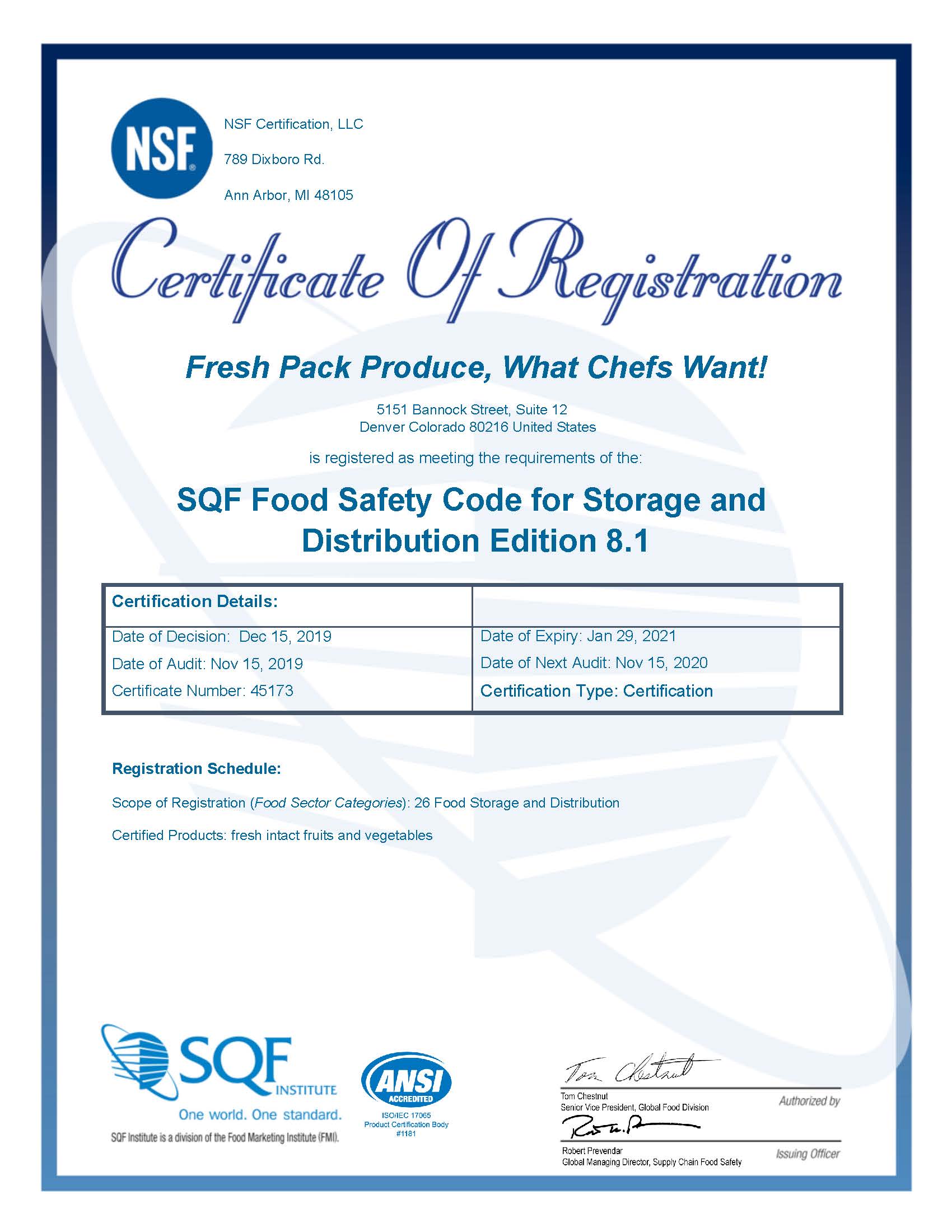

On an annual basis, Creation Gardens facilities are audited to GFSI benchmarked standards basis by independent 3rd party auditors. Audits are conducted to the SQF Code Edition 8 and encompass regulatory compliance, HACCP principles and prerequisite programs, Good Manufacturing Practices, Pest Control, Food Defense, Physical Building, Equipment, Delivery Practices, Allergen Controls, Chemical Policies, Building Security, and Managerial Processes.

Creation Gardens has a written food safety policy and all of Creation Gardens processes and products fall under the scope of a HACCP plan developed to address hazards specific to the process or product it is associated.

Creation Gardens has identified critical control points for the HACCP pertaining to manufacturing operations. CCPs are monitored, records are kept and reviewed regularly. As part of our continuing commitment to food safety, Creation Gardens reviews and documents the review of HACCP plans annually. Creation Gardens’ HACCP team is comprised of ten employees who have received training and are HACCP certified to recognize hazards associated with the food we produce. The HACCP team is responsible for maintaining our food safety program and HACCP plans.

In addition to HACCP, Creation Gardens follows Good Manufacturing Practices to ensure products are handled in a food safe manner. Employees are trained to understand and follow GMP’s while executing their duties. GMP quizzes are administered to employees to verify understanding of food safety principles. Records are kept and reviewed of these training exercises.

Creation Gardens documented sanitation program and SSOPs are a state of the art approach for the control of pathogens in production and processing areas of the facility and specifically addresses the concern for E.Coli 0157-h7 and Listeria Monocytogenes. We use a hot water and sanitizing foam cleaning method for sanitizing our meat and seafood processing areas, and food portioning areas of our facility. Environmental swabs for the processing and portioning areas are used as validation that our sanitation program is effective. Sanitation employees are properly trained to understand and follow SSOP, records are kept and maintained daily of cleaning and sanitation activities.

Creation Gardens has a documented allergen control policy. Creation Gardens currently warehouses and distributes all of the “big eight” allergens. Allergens are stored in such a way as to prevent cross contact contamination in the event of a spill or other eventuality. Products containing allergen are label accordingly to alert consignees of potential allergen hazards or possible known risks. Swabs are used as method to validate the effectiveness of our allergen control policy.

Creation Gardens has a documented and tested Traceability and Recall Program if there is an event or food safety crisis which products need to be withdrawn or recalled from the market place. Our food safety and HACCP teams have been trained to conduct a product recall in an effective and timely manner. Creation Gardens conducts mock recalls as a way of testing our preparedness during a real food safety emergency.

Creation Gardens is committed to providing our customers the highest quality, safest and legal products possible. In order to achieve this goal we follow HACCP principals, Good Manufacturing Practices and train our employees to understand quality issues and follow proper procedures. We receive and distribute wholesome products. Warehouse and distribution controls are maintained and recorded. Refrigeration machinery and distribution vehicles are kept in good order. Produce and grocery items not meeting specifications will not be shipped. Customer complaints are recorded and a company-wide approach is employed to ensure quality objectives are being met.